All Features

Anthony D. Burns

I had humble, that is, poor, beginnings. I didn’t even know the taste of real ice cream until later in life. One of the first impacts I felt of the luxury that technology brings was the diode my father bought for me to replace the cat’s whisker on my crystal radio. My high school was lovingly…

Kevin Meyer

One of the most powerful lean tools is called value stream mapping, a visual management method used to document the flow and creation of value in a process. The definition of a value stream is all steps—both value-added and nonvalue-added—that contribute to taking the process from raw materials to…

Therese Graff

A recent article in The Wall Street Journal (“The Reason Southwest Stopped Overbooking”), which contained excerpts from an interview with Southwest Airlines’ CEO Gary Kelly, brought out the need to address airline capacity issues on the ground and in the air. Responding to a question on the impact…

Dirk Dusharme @ Quality Digest

Our August 11, 2017, episode of QDL looked at the role of technology in after-market service, stairs that help you up, Fidget Cubes, and more.

“Climbing Stairs Just Got Easier With Energy-Recycling Steps”

These stairs actually help you go up.

“The Curious Case of the Fidget Cube”

How a product…

Gerald Friedman

It’s easier than ever to buy stuff. You can purchase almost anything on Amazon with a click, and it is only slightly harder to find a place to stay in a foreign city on Airbnb. So why can’t we pay for healthcare the same way?

My research into the economics of healthcare suggests we should be able…

Bruce Hamilton

At GBMP’s launch of the Shingo Institute’s Build Excellence workshop, it occurred to me that perhaps systems thinking might be more aptly named systems rethinking. Workshop participants offered up current systems in their organizations that actually impeded continuous improvement, each time…

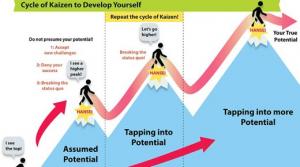

Jun Nakamuro

Japanese improvement techniques have been emulated across the globe for decades, and none carries more cultural weight than the theory of kaizen. When I expose Western leaders to lean practices in Japan, they often express that they have come away with a better understanding of “true kaizen.” They…

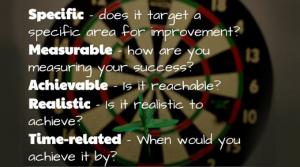

Ken Levine, Satish Nargundkar

Completing the define phase of a lean Six Sigma (LSS) project is a critical part of any project, although it’s often underestimated in practice. The define phase of the define, measure, analyze, improve, control (DMAIC) process typically includes three elements. The first is selecting a specific,…

John Guaspari

‘You want me to pull the kids out of school for what?”

I could tell that my wife didn’t like my idea because she had used the tone she uses when I say something that is, to employ the pet phrase she employs in such instances, “really stupid.”

“For Guaspari Family Quality Day,” I replied. “We take…

Steven Brand

Labor costs are likely the largest line item on your company balance sheet. Therefore, a successful cost-reduction strategy must adequately balance resourcing and cost controls.

Although laying off part of the workforce may seem like the quickest and easiest solution to reducing labor costs in…

Bruce Hamilton

On May 5, 1961, Alan Shepard became the first U.S. astronaut to journey to the “final frontier.” Atop a Mercury rocket, Shepard launched into a 15-minute suborbital journey reaching an altitude of about 100 miles before returning to Earth. His space capsule, Freedom 7, was a wonder of science,…

Harish Jose

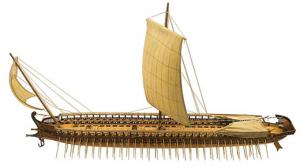

There is a great Greek paradox/puzzle called the Ship of Theseus. There are multiple versions and derivations to it. My favorite version is as follows (highly watered down).

Theseus bought a new ship. Each day he replaced one part of the ship. Plank by plank, sail by sail, and oar by oar. Finally…

Harish Jose

In today’s column, I will be looking at process validation and the problem of induction. Yesterday, I looked at process validation through another philosophical angle by using the lesson of the Ship of Theseus.

The U.S. Food and Drug Administration (FDA) defines process validation as “the…

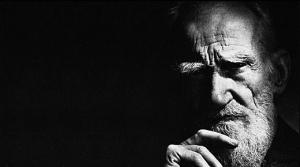

Gwendolyn Galsworth

The one complaint—the one problem—that nearly every company puts at (or very near) the top of its list of challenges is communication. George Bernard Shaw, the famous Irish playwright, sets us straight on this when he said: “The single biggest problem in communication is the illusion that it has…

Mike Richman

The June 30, 2017, episode of QDL offered a wrinkle in time, of sorts: not only orbiting debris and medieval medicine, but moments in the here and now such as our interview with Keith Bevan of the Coordinate Metrology Society and the UK’s National Physical Laboratory, and an on-the-go version of…

Kevin Meyer

Before you can improve something, you must first have a very clear understanding of what its current state is. Don’t assume you know what it is. Go to the gemba, be it the factory floor, the shipping and receiving area, your office, or even take a minute to focus on yourself, and observe what is…

Douglas C. Fair

Plant-floor quality issues tend to focus on a company’s technical resources. When products fall out of spec, alarms sound and all hands are immediately on deck to fix things. Despite large technology investments to monitor and adjust production processes, manufacturers are still bedeviled by…

Michael Ray Fincher

To meet the 2018 deadline for becoming certified to ISO 9001:2015, organizations are scrambling to overhaul their quality management systems. One major revision to ISO 9001 is the requirement to identify, evaluate, and address risks. Unfortunately, a tool most appropriate for these actions has…

Christopher Martin

Many of us are familiar with the concept of the Ohno Circle, innovated by Taiichi Ohno at Toyota during the 1940s. While familiarity with the technique and the goals it sets to accomplish is one thing, how many of us have actually participated? The surprising answer is… probably all of us, in a…

Robert A. Brown

Lean thinking has taken its rightful place in the effort to improve efficiency in manufacturing. However, it isn’t fulfilling its potential in many areas, most notably with knowledge workers. This is due to a fundamental flaw in how lean is presented and utilized. With a better constructed…

Bonnie Stone

18:37:21

In part one of “New Spin on the ‘Stand in a Circle’ Exercise,” I described how Taiichi Ohno, the creator of the Toyota Production System, used the “Stand in a Circle” exercise to help managers identify waste in their operations.

During this exercise Ohno would take a manager or student…

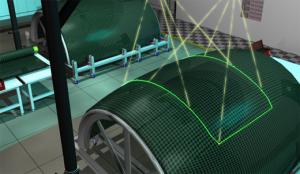

Ryan E. Day

Sponsored Content

Building airplanes and spaceships poses some of the most unique engineering and manufacturing challenges mankind has ever encountered. Fortunately, you don’t have to build rockets to benefit from rocket science. Manufacturers of most any product can improve their efficiency and…

Bonnie Stone

During the mid-1940s, Taiichi Ohno established the Toyota Production System, which is primarily based on eliminating nonvalue-added waste. He discovered that by reducing waste and inventory levels, problems get exposed and that forces employees to address these problems. To engage the workers and…

Laurel Thoennes @ Quality Digest

You can be known as a hard worker and counted on to tie up loose ends, but fall behind when co-workers’ tasks are on hold until yours are complete, and you’re perceived as needing an attitude adjustment. What would you want to do? Place blame or work on a remedy? There is a solution: Personal…

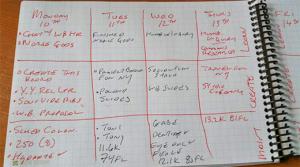

Jim Benson

There are those days where your personal kanban is on fire. You’re in a state of flow and tickets are just moving right along. The days go by and you look at your “done” column… it’s full. Really, really full.

The “done” tickets seem to swim. There are so many of them! You’ve been productive, but…