All Features

Markus Grau

Industry 4.0, cyber-physical systems, or the internet of things (IoT): the paradigm shift in the production economy is cheerfully progressing under various names. What they all refer to is the digitalization and networking of production processes and environments. The idea is by no means new. The…

Bruce Hamilton

Speaking at the 2003 Shingo Conference, Guy Briggs, general manager of North American operations for General Motors lamented, “We spent the 1980s ‘counting robots’ before we realized that it’s people that make the difference in our business.”

He was alluding to the thirty-five billion (yes,…

Jim Benson

People are always asking us for help with ways to prioritize. Almost everyone believes prioritization to be an action in and of itself. They ask, “What mechanisms do you use to prioritize?” However, we find most often that prioritization issues, like trust issues, are a symptom of deeper problems…

Harish Jose

I recently read Jordan Ellenberg’s wonderful book, How Not To Be Wrong: The Power of Mathematical Thinking (Penguin Books, 2014). I found the book to be enlightening and a great read. Ellenberg has the rare combination of being knowledgeable and capable of teaching in a humorous and engaging way.…

Trevor Blumenau

How does one define quality in the context of a warehouse? The perfect warehouse is clean, has everything in its place, and is easy to access. Your warehouse looks like the one below, right?

You have a perfectly accurate database table that tells you exactly where everything is, correct? And…

Bonnie Stone

Lean, also known as “lean manufacturing” or “lean production,” focuses on maximizing customer value by removing waste and eliminating defects. Lean tools are about understanding the process, looking for waste, preventing mistakes, and documenting what you did.

Let’s look at five lean tools used…

Tonianne DeMaria

Lean says: Manage flow. Your brain says: My work isn’t linear. My day is filled with interruptions, and so I don’t have the “luxury” of flow. What’s at play here: functional fixedness.

If there is one area where there’s not an obvious transfer of lean principles from manufacturing to knowledge…

Jordan Kraemer

During the past year, I stopped responding to customer surveys, providing user feedback or, mostly, contributing product reviews. Sometimes I feel obligated—even eager—to provide this information. Who doesn’t like being asked his opinion? But, in researching media technologies as an anthropologist…

Kevin Meyer

Changing an organization’s structure seems to be the common knee-jerk response to internal issues. My prior company embarked on a reorganization to eliminate arbitrary site- and function-based structures so that we could align around corporatewide value creation processes.

During the…

Mike Richman

During the Nov. 3, 2017, episode of QDL, we (figuratively) traveled the globe to bring you quality information. Let’s take a closer look:

“‘Made in Japan’ Falls from Grace Amid Scandals, Systematic Flaws in Manufacturing Industry” Kobe Steel is the latest Japanese manufacturer to admit to…

Tonianne DeMaria

Lean says: Map the value stream. Your brain says: I’ve been doing this so long, it’s become second nature to me. The steps are right here—in my head.

What’s at play here: • Illusion of transparency • Curse of knowledge/information imbalance • Status quo thinking • Groupthink/false consensus…

Harish Jose

Today I will look at epistemology at the gemba. Epistemology is the part of philosophy that deals with the theory of knowledge. It tries to answer the questions, “How do we know things, and what are the limits of our knowledge?” I have been learning about epistemology for a while now, and I find…

Bruce Hamilton

The first two books I ever read about lean were Zero Inventories (McGraw-Hill, 1983) by Robert Hall, and Japanese Manufacturing Techniques (Free Press, 1982) by Richard Schonberger. In 1985, these definitive academic works were among just a few sources of information about what was then referred…

Jun Nakamuro

The world first became aware of the Toyota Production System (TPS) when Taiichi Ohno published a book about his groundbreaking efforts at Toyota. It was published in Japan in 1978. The Japanese version of his book wasn’t translated into English until 1988. Because 10 years had passed, this…

Matthew Barsalou

Quality tools can serve many purposes in problem solving. They may be used to assist in decision making, selecting quality improvement projects, and in performing root cause analysis. They provide useful structure to brainstorming sessions, for communicating information, and for sharing ideas with…

jeffdewar

This photo shows the Milky Way (from the Latin via lactea), part of our galaxy as seen from Earth. It’s a barred spiral galaxy, essentially a flat disk of at least 100 billion stars. Our galaxy is just one of about 400 billion in the universe, only three of which can be seen by the naked eye.…

Gwendolyn Galsworth

When James Womack and Daniel Jones published Lean Thinking in 1996, they offered the world a book that collected the core principles of a key operational model. Though not stated directly, they created a profile for the Toyota Production System (TPS) that was revelatory and highly useful, adding a…

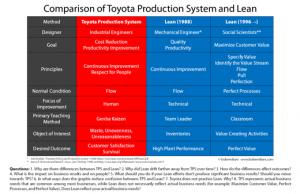

Bob Emiliani

I recently posted a version of the graphic below with the caption: “Not perfect, but close. It’s about right.” The response was overwhelmingly positive. A great majority of people recognized it as a unique comparison, one that they had never seen before, and also as an accurate comparison that…

William A. Levinson

Some ISO 9001 users complain that the standard does not improve performance or deliver bottom-line results, while others are delighted by the standard as a framework for effective quality management systems. I pointed out previously that ISO 9001:2015 does not address, at least not explicitly, the…

Tonianne DeMaria

While heading to a session at the most recent Lean Transformation Summit, I found myself confronted with signage that posed the following open-ended question: “All problem solvers must....”

Given how the work we do at Modus Cooperandi focuses largely on the nexus between lean for knowledge work,…

Jim Benson

Focusing on our most important work (so that we can get it out the door and create value) is hard. It’s harder still when work suddenly picks up, is unfamiliar, or arrives with immediate deadlines when we are already busy.

The tyranny of the urgent often distracts us from what is truly important…

GBMP

American Rheinmetall Systems (ARS) LLC, formerly Vingtech, is located in Biddeford, Maine. Established in January 2007, as part of a Norwegian company that had received a supplier contract for the U.S. Army’s CROWS remote weapon station program, the company was acquired by the Rheinmetall Group in…

Mike Richman

QDL from Fri., Sept. 15, 2017, demonstrated that everywhere you look, you’ll find the positive effect of better quality. Here’s what we chatted about:

““U.S. Business Sectors Gain or Hold Steady in Public Esteem”

According to a recent Gallup survey, U.S. citizens’ outlook on a number of industries…

Christopher Martin

It’s said that the first five years of children’s lives are important to their future development and growth. Most of that is spent at home with parents and loved ones, before children are thrust into the first stage of their next 13 years of development: kindergarten. Being a parent of two…

Jon Speer

Medical device startups tend to share many common issues. They are usually striving for better resources (such as people and capital) as well as the knowledge and expertise required to deal with the U.S. Food and Drug Administration (FDA) and successfully bring a product to market.

For many…