The control chart is at the heart of the very definition of quality. It is central to building, maintaining, and predicting quality into the future. However, control charts today, more often than not, are misused and misunderstood. The aim of this article is to show not only how control charts are misunderstood, but also how control charts, when properly understood, are easy to use by any employee.

|

ADVERTISEMENT |

A bit of history

Mass production dates back 2,200 years to China, but it wasn’t until the Industrial Revolution at the start of the 19th century that it became commonplace. Mass production brought with it the need for identical and interchangeable parts, along with control of manufacturing processes. For example, in the 1860s during the American Civil War, interchangeability was key in using the Minié ball in both the U.S. Springfield and British Enfield rifles. Interchangeability was also important in watchmaking and in sewing machines at this time. The need for interchangeability of parts made good quality essential.

…

Comments

Control charts for count of jobs per day

Most count charts I see are proportion. What about for count if jobs completed per day

Count data

Hi Jason,

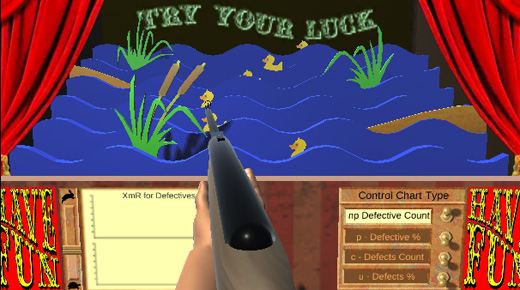

Did you have a look at the interactive training exercise example, from Q-Skills3D? It should address your question. It shows the effectiveness of XmR with the 4 types of count data. View it on a PC (non IE).

You can also view it on a mobile by installing the full Q-Skills3D, training in quality and Lean, from the Google Android and Apple app stores. Q-Skills3D is the only quality training on both mobiles and PC. Q-Skills3D builds on the success of Q-Skills, with over 500,000 users.

Thanks for the reply, i will

Thanks for the reply, i will check it out

Control Charts Misnamed

Unfortunately, Shewhart set quality back a century by naming these charts "Control" charts. 100 years after Shewhart created control charts, they are rarely found outside of manufacturing factory floors. Yet 80% of American businesses are service industries where control chart usage is minimal to nonexistent.

Most people, especially Americans, do not respond well to word "control." Wheeler has been trying to rename them "process behavior charts" which is on the right track but perhaps too long and bland.

If we start calling them what they are, Performance Charts, perhaps more people will take notice. Everyone seems to want to improve their performance while few want to improve their control or their process behavior.

I disagree that you don't need software to do control charts, otherwise they would be in every business everywhere.

Control Charts Misnamed

Unfortunately, Shewhart set quality back a century by naming these charts "Control" charts. 100 years after Shewhart created control charts, they are rarely found outside of manufacturing factory floors. Yet 80% of American businesses are service industries where control chart usage is minimal to nonexistent.

Most people, especially Americans, do not respond well to word "control." Wheeler has been trying to rename them "process behavior charts" which is on the right track but perhaps too long and bland.

If we start calling them what they are, Performance Charts, perhaps more people will take notice. Everyone seems to want to improve their performance while few want to improve their control or their process behavior.

I disagree that you don't need software to do control charts, otherwise they would be in every business everywhere.

Process Behaviour Charts

I prefer "process behaviour chart" but "control chart" gets 1,400 times more Google hits. It is what people know ... or think they know.

"Performance chart" can mean just about anything.

It is not lack of software that limits the use of process behaviour charts. There is ample free software available to draw them. The more expensive the charting software, the more likely people are to make a mess of them, such as by normalization.

If people kept process behavior charts simple as Dr Shewhart did, and if all employees were trained as Professor Deming advocated, we were see much more of this powerful tool that is fundamental to quality.

misnamed control charts

I do not agree Dr. Shewhart misnamed his charts. Nobody was more careful with words I have read. There is however, no short name that will communicate all they will do. No perfect name. Why the name control?

Shewhart asks: How far can Man go in controlling his physical environment? How does this depend upon the human factor of intelligence and how upon the element of chance?

I do appreciate Dr. Wheeler attempting to use simpler language as well as Dr. Deming. In hindsight, maybe just one name is better.

Great article!

Add new comment